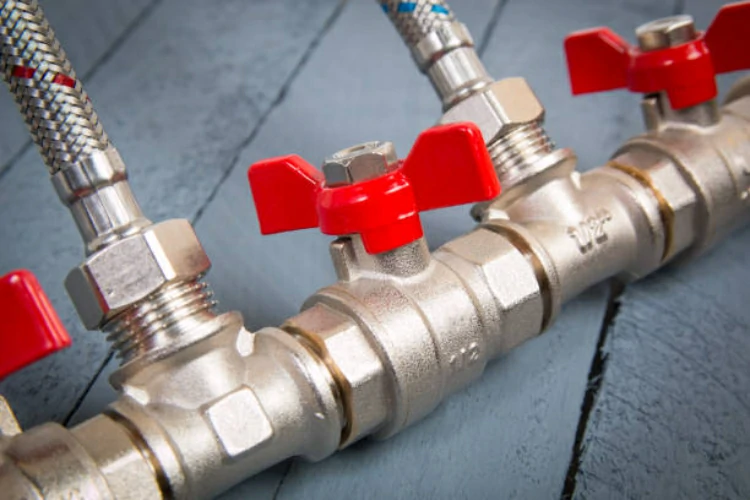

Stainless steel stop valves are a vital component in various plumbing and industrial systems, offering a range of benefits that make them a preferred choice for many applications. Understanding the advantages of these valves can help in making informed decisions for your specific needs. This article delves into the key benefits of stainless steel stop valves, focusing on their durability, corrosion resistance, and overall performance.

Durability and Strength

High-Quality Material

Stainless steel stop valves are made from high-grade stainless steel, which ensures exceptional strength and longevity. This material is known for its robust nature and ability to withstand harsh conditions.

Longevity:

The high-quality stainless steel used in these valves ensures that they have a long service life, reducing the need for frequent replacements and maintenance.

Robust Construction:

The sturdy construction of stainless steel stop valves makes them ideal for applications that involve high pressure and extreme temperatures.

Resistance to Wear and Tear

One of the most significant advantages of stainless steel stop valve is their resistance to wear and tear. This makes them highly reliable in demanding environments.

- Minimal Maintenance: Due to their durability, these valves require minimal maintenance, which translates to lower operational costs over time.

- High Pressure Handling: Stainless steel stop valve can handle high-pressure environments without deformation or failure, ensuring consistent performance.

Corrosion Resistance

Superior Corrosion Resistance

Stainless steel is renowned for its excellent corrosion resistance, which is a crucial factor in valve selection for many industries.

Chemical Resistance:

Stainless steel stop valve are resistant to a wide range of chemicals, making them suitable for use in chemical processing industries and other harsh environments.

Water Resistance:

These valves are also highly resistant to corrosion caused by water, which is essential for plumbing and marine applications.

Enhanced Lifespan

The corrosion resistance of stainless steel stop valve significantly enhances their lifespan, providing long-term reliability and performance.

Reduced Corrosion Impact:

By resisting corrosion, these valves maintain their structural integrity and functionality over time, even when exposed to corrosive substances.

Sustained Efficiency:

Stainless steel stop valve remain efficient and operational for extended periods, ensuring consistent flow control and minimal downtime.

Performance and Versatility

Precision and Control

Stainless steel stop valves offer precise control over fluid flow, which is essential for various applications that require accurate flow regulation.

Flow Regulation:

These valves allow for precise throttling and flow control, making them suitable for applications where exact flow rates are necessary.

Leak Prevention:

The design of stainless steel stop valve ensures a tight seal, preventing leaks and maintaining system efficiency.

Versatile Applications

The versatility of stainless steel stop valve makes them ideal for a wide range of applications across different industries.

Industrial Use:

These valves are widely used in industries such as oil and gas, chemical processing, and power generation due to their robustness and reliability.

Residential and Commercial Plumbing:

Stainless steel stop valve are also popular in residential and commercial plumbing systems, providing dependable performance and longevity.

Environmental Considerations

Stainless steel is an environmentally friendly material, adding another layer of advantage to the use of stainless steel stop valves.

Recyclability:

Stainless steel is 100% recyclable, which means that at the end of its life cycle, the valve can be recycled, reducing its environmental footprint.

Sustainability:

The long lifespan and durability of stainless steel stop valve contribute to sustainability by reducing the need for frequent replacements and conserving resources.

Conclusion

Stainless steel stop valves offer numerous advantages, including exceptional durability, superior corrosion resistance, and versatile performance. These attributes make them a preferred choice for various applications, from industrial settings to residential plumbing systems. By understanding the benefits of stainless steel stop valve, you can make informed decisions that ensure reliable, long-lasting, and efficient performance in your plumbing and industrial systems.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://pipefittingpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments