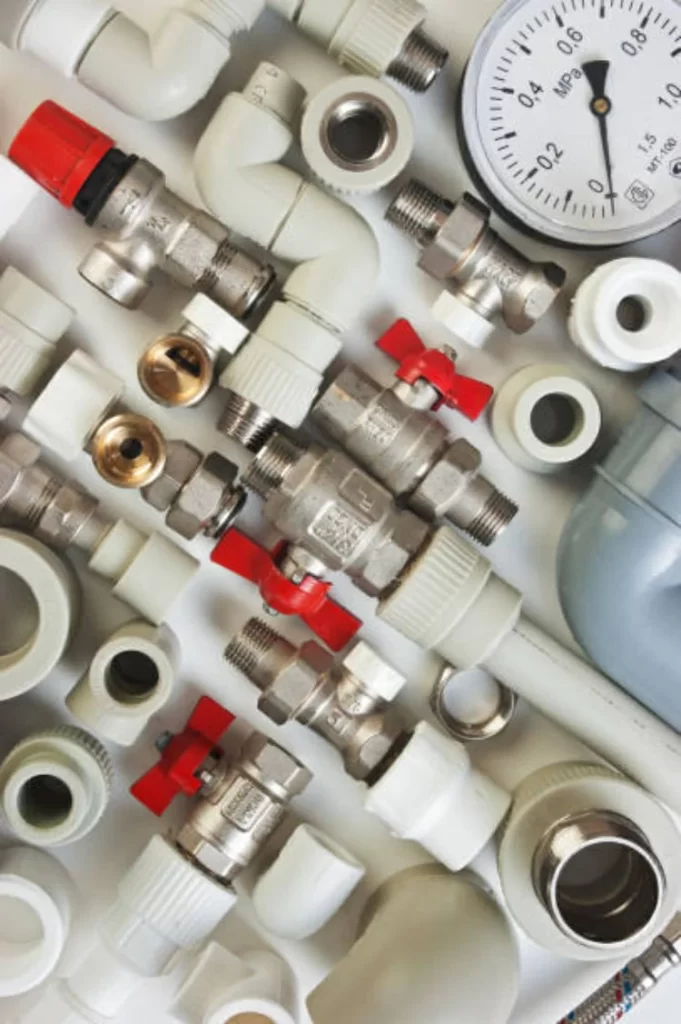

When choosing between brass stop valves and gate valves, it’s essential to understand their unique features and applications. These two types of valves are fundamental in various plumbing systems, but they serve distinct purposes. This article explores the primary differences between brass stop valves and gate valves, focusing on their design, functionality, and best use cases.

Design and Construction

Brass Stop Valves

Brass stop valves, often referred to as globe valves, have a distinctive design that includes a movable disk and a spherical body. This design allows for precise control over fluid flow.

Internal Structure:

The brass stop valve’s internal structure comprises a disk that moves up and down to regulate fluid flow. When the handle is turned, the disk presses against a seat to stop the flow or lifts to allow passage.

Flow Control:

One of the significant advantages of brass stop valves is their ability to control flow precisely. This makes them ideal for applications where throttling or frequent adjustments are necessary.

Material and Durability:

Brass as a material offers excellent corrosion resistance and durability, making brass stop valves suitable for both residential and industrial applications.

Gate Valves

Gate valves, in contrast, feature a gate-like mechanism that moves vertically to block or allow fluid flow. Their design is more straightforward compared to brass stop valves.

Internal Mechanism:

The gate valve uses a gate or wedge that, when fully lifted, allows fluid to pass through unobstructed. Lowering the gate blocks the flow completely.

Flow Efficiency:

Gate valves are designed for minimal pressure drop when fully open, making them ideal for applications requiring maximum flow efficiency.

Construction Material:

Gate valves can be made from various materials, including brass, which provides good corrosion resistance, though they are also available in other materials for different applications.

Functionality and Operation

Brass Stop Valves

The primary functionality of brass stop valves is to regulate and control fluid flow. They are versatile and used in various systems requiring precise flow adjustments.

Regulation and Throttling:

Brass stop valve excel in applications where fine control over flow rate is needed. Their design allows for gradual adjustment, which is not possible with gate valves.

Pressure Handling:

These valves can handle higher pressures effectively, making them suitable for high-pressure systems in residential, commercial, and industrial settings.

Maintenance and Repair:

Brass stop valves are relatively easy to maintain. The design allows for straightforward replacement of internal components without needing to remove the entire valve from the system.

Gate Valves

Gate valves are primarily used to start and stop fluid flow with minimal resistance when fully open. They are not designed for flow regulation.

On/Off Control:

The main advantage of gate valves is their ability to provide unobstructed flow when fully open and complete shut-off when closed. This makes them ideal for applications where flow needs to be either fully on or off.

Pressure Drop:

When open, gate valves offer minimal pressure drop, which is beneficial in systems where maintaining flow efficiency is crucial.

Operational Simplicity:

Users can operate gate valves easily, often employing them in applications where the valve stays in a fixed position (either fully open or fully closed) for extended periods.

Application Scenarios

Brass Stop Valves

Brass stop valves are suitable for a wide range of applications due to their precise control and durability.

Residential Plumbing:

Household plumbing systems commonly use these valves for faucets, shower controls, and other fixtures requiring precise flow regulation.

Industrial Use:

In industrial settings, brass stop valve control the flow of various fluids, including gases and liquids, in manufacturing processes.

HVAC Systems:

Heating, ventilation, and air conditioning systems also use brass stop valves to regulate coolant flow.

Gate Valves

Gate valves find their use in scenarios where full flow or complete shut-off is required.

Water Supply Systems:

Water supply lines frequently use gate valves to control large volumes of water with minimal resistance.

Irrigation Systems:

In agricultural settings, gate valves control the flow of water in irrigation systems, ensuring efficient water distribution.

Fire Protection Systems:

Gate valves are essential in fire protection systems where they can quickly allow or stop the flow of water to sprinkler systems.

Conclusion

While both brass stop valves and gate valves play crucial roles in plumbing systems, they are designed for different purposes. Brass stop valves offer precise flow control and are versatile in various applications, whereas gate valves provide efficient on/off control with minimal pressure drop. Understanding these differences will help you choose the right valve for your specific needs, ensuring optimal performance and durability in your plumbing system.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://pipefittingpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments