Installing PEX pipes requires careful planning and execution to ensure optimal performance and longevity of the plumbing system. Below is a step-by-step guide outlining the installation process of PEX pipe for various applications.

Step 1: Planning and Preparation

1. Assessing the Plumbing Layout:

Before beginning the installation, carefully assess the plumbing layout to determine the best routing for the PEX pipes. Consider factors such as water supply points, fixture locations, and any obstacles or obstructions that may affect the routing.

2. Selecting the Right PEX Type:

Choose the appropriate type of PEX pipe for the application, considering factors such as temperature and pressure requirements, as well as compatibility with fittings and connections.

3. Gathering Tools and Materials:

Ensure you have all the necessary tools and materials on hand, including PEX pipes, fittings, crimp rings or clamps, a PEX tubing cutter, a crimping tool or clamp tool, and a measuring tape.

Step 2: Cutting and Fitting the PEX Pipes

1. Cutting the Pipes:

Measure and mark the PEX pipes according to the planned layout, then use a PEX tubing cutter to make clean, straight cuts. Ensure the cuts are square to facilitate proper fitting and sealing.

2. Fitting the Pipes:

Insert PEX fittings into the ends of the pipes, ensuring they are fully seated and aligned. Use the appropriate method for securing the fittings, such as crimp rings or stainless-steel clamps, following the manufacturer’s instructions.

Step 3: Routing and Securing the Pipes

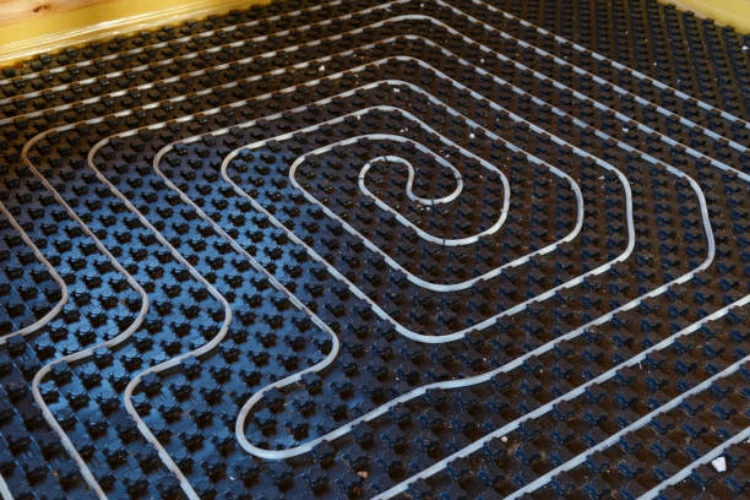

1. Routing the Pipes:

Carefully route the PEX pipes along the planned path, taking care to avoid sharp bends or kinks that could restrict water flow. Support the pipes at regular intervals using pipe clips or straps to prevent sagging or movement.

2. Securing the Pipes:

Secure the PEX pipes to structural elements such as studs or joists using appropriate fasteners. Maintain proper spacing between the pipes and other building materials to prevent damage or friction.

Step 4: Making Connections

1. Installing Shutoff Valves:

Install shutoff valves at key points along the plumbing system, such as at fixture supply lines or branch connections. This allows for easy isolation of sections of the system for maintenance or repairs.

2. Connecting to Fixtures:

Connect the PEX pipes to plumbing fixtures using appropriate fittings, such as adapters or compression fittings. Ensure the connections are tight and secure to prevent leaks.

Step 5: Pressure Testing and Inspections

1. Pressure Testing:

After completing the installation, perform a pressure test on the plumbing system to check for leaks or weaknesses. Pressurize the system to the recommended pressure and monitor for any drops in pressure over time.

2. Inspections and Final Checks:

Inspect the entire plumbing system for any signs of leaks, damage, or improper fittings. Make any necessary adjustments or repairs before completing the installation.

Conclusion

Proper installation of PEX pipes is essential for ensuring the reliability and efficiency of plumbing systems in residential, commercial, and industrial applications. By following the step-by-step guide outlined above and adhering to industry best practices, installers can create durable and leak-free plumbing systems that meet the highest standards of performance and safety.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://pipefittingpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments