Introduction: The Art of Installing Brass Fittings

Installing brass fittings is a crucial step in the construction or maintenance of any plumbing system. Whether you’re a seasoned professional or a DIY enthusiast, understanding the proper installation techniques is essential for ensuring the reliability, efficiency, and longevity of your plumbing setup. In this guide, we’ll delve into the intricacies of installing brass fittings, covering everything from preparation and assembly to testing and maintenance.

Preparation: Setting the Stage for Success

- Gather Your Materials: Before beginning the installation process, gather all the necessary materials and tools, including brass fittings, pipes, pipe wrenches, thread sealant, and Teflon tape. Having everything on hand will streamline the installation process and minimize delays.

- Inspect the Components: Take a moment to inspect the brass fittings and pipes for any defects or damage. Look for cracks, dents, or imperfections that could compromise the integrity of the plumbing system. Replace any faulty components before proceeding with the installation.

- Measure and Plan: Measure the dimensions of the plumbing system and plan the layout of the fittings accordingly. Ensure that you have sufficient clearance and access for assembling and tightening the fittings. Double-check your measurements to avoid errors during installation.

Assembly: Piecing It All Together

- Apply Thread Sealant: Before assembling the brass fittings, apply a thin layer of thread sealant or Teflon tape to the male threads. This will help create a tight seal and prevent leaks once the fittings are installed. Be careful not to over-apply the sealant, as excess material can interfere with the threading process.

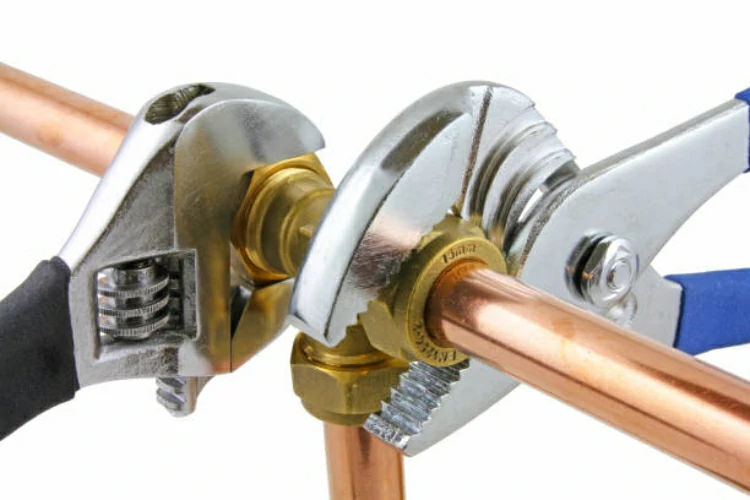

- Hand-Tighten the Fittings: Begin assembling the brass fittings by hand-tightening them onto the corresponding pipes. Use a pipe wrench to secure the fittings in place, ensuring a snug fit without over-tightening. Avoid using excessive force, as this can damage the fittings or strip the threads.

- Check Alignment and Orientation: As you assemble the brass fittings, periodically check their alignment and orientation to ensure they are positioned correctly. Use a level or straightedge to verify that the pipes and fittings are aligned properly, especially in horizontal or vertical runs.

Testing and Maintenance: Ensuring Reliability and Performance

- Perform a Pressure Test: Once the brass fittings are installed, conduct a pressure test to check for leaks or weaknesses in the plumbing system. Use a pressure gauge to pressurize the system to the recommended level and inspect the fittings for any signs of leakage. Address any issues promptly to prevent water damage or loss.

- Regular Maintenance: To maintain the integrity of the brass fittings and prolong their lifespan, implement a regular maintenance schedule. Inspect the fittings periodically for signs of wear, corrosion, or damage, and replace any faulty components as needed. Keep the fittings clean and free from debris to prevent blockages or obstructions.

Conclusion: Mastering the Art of Brass Fitting Installation

Mastering the installation of brass fittings is essential for ensuring the reliability, efficiency, and longevity of your plumbing system. By following the steps outlined in this guide and exercising care and precision during the installation process, you can create a robust and leak-free plumbing setup that will serve you well for years to come. Remember to prioritize proper preparation, careful assembly, thorough testing, and regular maintenance to keep your brass fittings in optimal condition.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://pipefittingpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments