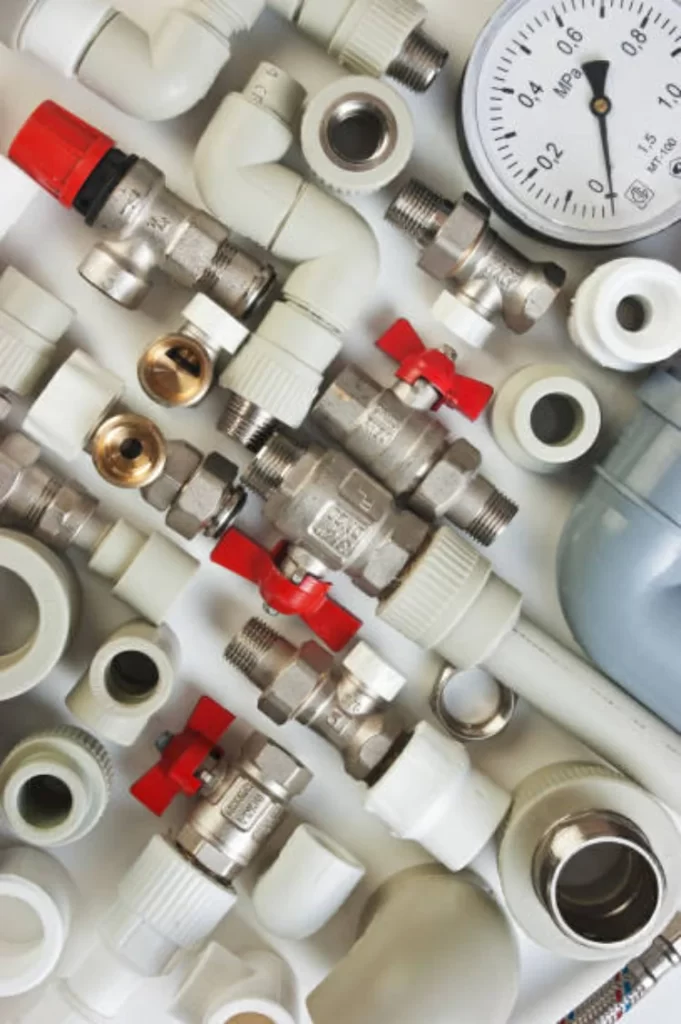

Introduction to Brass Ball Valves

Brass ball valves are indispensable components in plumbing and industrial systems, renowned for their durability and versatility. A key factor contributing to their superior performance is the choice of materials. Among these, copper alloys, particularly brass, stand out for their exceptional properties and wide-ranging applications.

Advantages of Brass in Ball Valve Manufacturing

1. Corrosion Resistance

Brass, a copper-zinc alloy, exhibits remarkable resistance to corrosion, making it an ideal choice for ball valve construction. The addition of zinc enhances its ability to withstand harsh environments, including exposure to moisture and various chemicals. This corrosion resistance ensures prolonged valve lifespan, even in demanding applications such as water treatment plants and chemical processing facilities.

2. High Machinability

One of the most significant advantages of brass is its high machinability, which facilitates intricate valve designs and precise manufacturing processes. This property allows for the creation of intricate valve components with tight tolerances, ensuring optimal performance and reliability. Additionally, brass’s machinability enables cost-effective production, making brass ball valves an economical choice for numerous applications.

3. Excellent Thermal Conductivity

Brass possesses excellent thermal conductivity, facilitating efficient heat transfer within the valve assembly. This property is particularly advantageous in applications where temperature control is critical, such as HVAC systems and industrial process piping. By efficiently dissipating heat, brass ball valves help maintain system stability and prevent overheating, ensuring smooth operation even under extreme conditions.

4. Superior Sealing Properties

Another notable advantage of brass ball valves is their superior sealing properties, essential for preventing leaks and ensuring system integrity. Brass’s malleability allows for precise machining of valve components, enabling tight seals between the ball and the valve body. This tight seal minimizes the risk of leakage, enhancing safety and reducing the likelihood of costly downtime or environmental damage.

5. Enhanced Durability

Brass ball valves are renowned for their exceptional durability, capable of withstanding high pressures and temperatures without compromising performance. The inherent strength of brass, combined with its corrosion resistance, ensures long-term reliability in a wide range of operating conditions. As a result, brass ball valves are preferred across various industries, including oil and gas, water treatment, and manufacturing.

Applications of Brass Ball Valves

1. Plumbing Systems

Brass ball valves are extensively used in residential, commercial, and industrial plumbing systems for controlling the flow of water and other fluids. Their corrosion resistance, durability, and ease of installation make them a preferred choice for shut-off and isolation applications in pipelines, water heaters, and irrigation systems.

2. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, brass ball valves play a crucial role in regulating fluid flow and controlling system operation. Their thermal conductivity and resistance to corrosion make them suitable for both heating and cooling applications, ensuring efficient performance and system longevity.

3. Industrial Processes

Brass ball valves find widespread use in various industrial processes, including chemical processing, petroleum refining, and manufacturing. Their ability to withstand corrosive chemicals, high temperatures, and extreme pressures makes them indispensable for controlling the flow of fluids in critical production processes, ensuring operational safety and efficiency.

Conclusion

Brass ball valves, crafted from copper-zinc alloys, offer numerous advantages that make them indispensable in a wide range of applications. Their exceptional corrosion resistance, high machinability, thermal conductivity, sealing properties, and durability make them the preferred choice for plumbing, HVAC, and industrial systems worldwide. By understanding the advantages of brass in ball valve manufacturing, engineers and facility managers can make informed decisions to optimize system performance and reliability.

IFAN is a Chinese manufacturer of plastic pipes, fittings and valves with 30 years of experience. If you are interested in IFAN copper fittings, copper valves, plastic pipes and fittings, please contact us. IFAN offers you a variety of standard pipes to meet your specific needs. Click below to learn more about IFAN’s wide range of affordable and cost-effective valve products and piping system related products.

We will reply your email or fax within 24 hours.

You can call us at any time if there is any question on our production.

For more information,pls visit our webside https://pipefittingpro.com/

Pls Mailto: [email protected]

Whatsapp: + 86 19857948982

Recent Comments